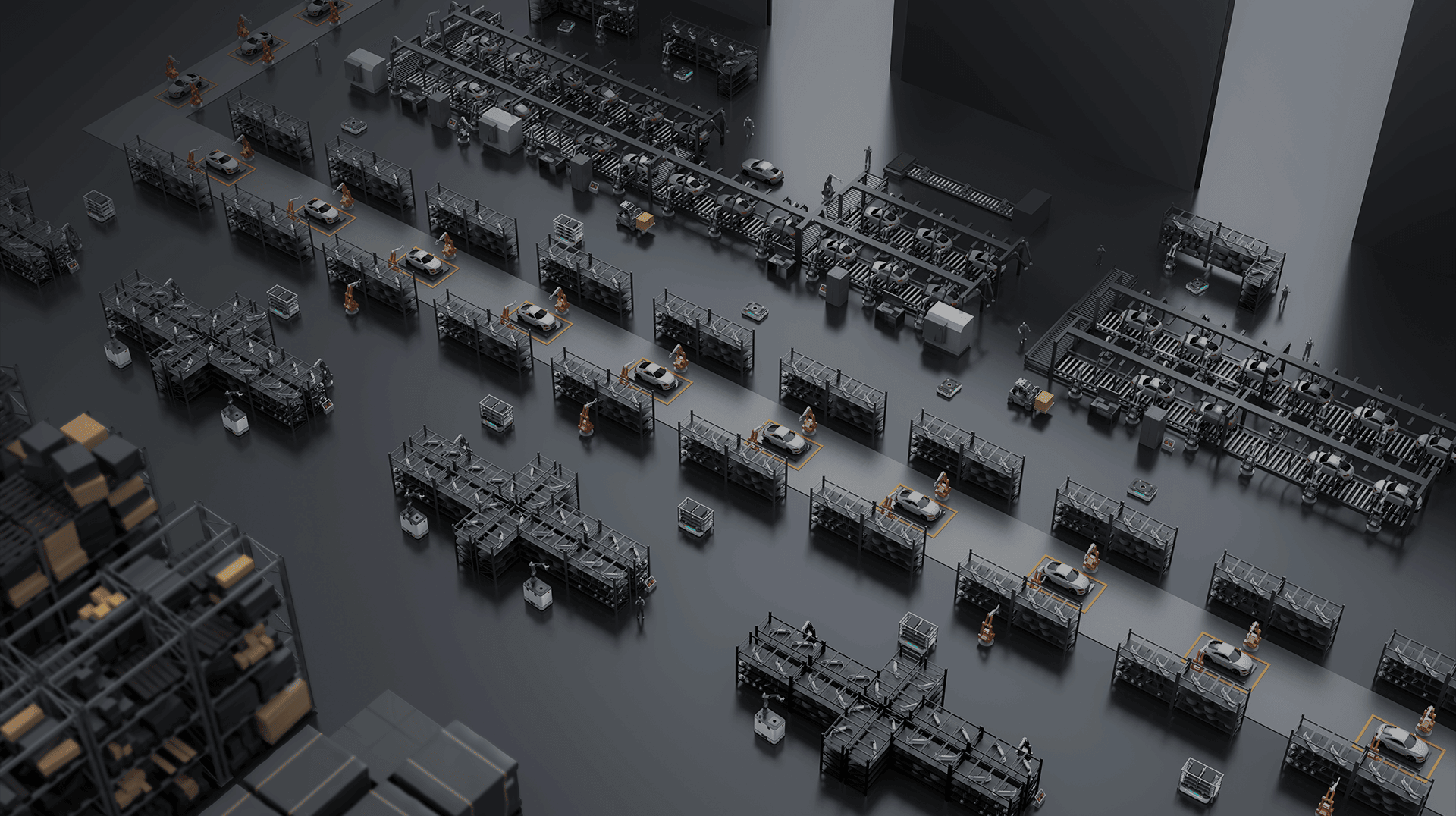

The world of industrial automation has brought about a significant transformation in the manufacturing industry. With advanced technologies and innovative solutions, industrial automation has revolutionized production processes, increasing efficiency and productivity.

The Power of Industrial Automation

Industrial automation refers to the use of control systems, such as robots or computers, to handle various tasks in manufacturing plants. It involves integrating machinery and software to automate repetitive tasks, streamline operations, and enhance overall performance.

This technology enables manufacturers to achieve higher levels of precision, accuracy, and consistency in their production processes. By reducing human intervention and minimizing errors caused by manual labor, industrial automation ensures better quality products at a faster pace.

Moreover, it allows companies to optimize resource utilization by monitoring energy consumption and minimizing waste generation. This not only contributes to cost savings but also promotes sustainability in manufacturing practices.

Youibot: A Pioneer in Industrial Automation

Youibot is an exemplary company that specializes in providing cutting-edge solutions for industrial automation. They offer a wide range of robotic systems designed specifically for different industries’ needs.

With Youibot’s advanced robotics technology, manufacturers can automate complex tasks that were previously time-consuming or hazardous for workers. Their robots are equipped with state-of-the-art sensors and intelligent algorithms that enable them to navigate autonomously within factory environments while avoiding obstacles efficiently.

Youibot’s commitment to innovation has led them to develop collaborative robots (cobots) that can work alongside humans safely. These cobots are designed with built-in safety features like force sensing capabilities that allow them to detect any unexpected contact with humans or objects nearby instantly.

AGV vs AMR: Choosing the Right Solution

In the realm of industrial automation, two popular technologies are Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs). While both serve the purpose of automating material handling tasks, they differ in their capabilities and applications.

AGVs are guided by predefined paths or markers on the floor, making them suitable for repetitive tasks within a fixed environment. On the other hand, AMRs utilize advanced navigation systems like LiDAR and SLAM to move autonomously without any physical guidance. This makes AMRs more flexible and adaptable to dynamic environments.

When deciding between AGVs and AMRs, manufacturers need to consider factors such as facility layout, task complexity, scalability requirements, and budget constraints. It is essential to choose the solution that best aligns with specific operational needs to maximize efficiency gains.

The Future of Industrial Automation

As industrial automation continues to evolve rapidly, its impact on the manufacturing industry will only grow stronger. The integration of artificial intelligence (AI), machine learning algorithms, and big data analytics will further enhance automation capabilities.

This technology-driven transformation will enable manufacturers to achieve higher levels of productivity while reducing costs associated with labor-intensive processes. Additionally, it will create new job opportunities that require specialized skills in robotics programming and maintenance.

In conclusion,

industrial automation

has revolutionized manufacturing by improving efficiency, enhancing product quality, optimizing resource utilization, ensuring workplace safety,

Click agv vs amr..