The global fertilizer market is projected to reach a staggering $200 billion by 2025, underscoring the critical role of efficient production and distribution systems. Among these systems, the BB Fertilizer Making machine stands out as a pivotal component in optimizing transportation attributes within the agricultural supply chain.

An Overview of the BB Fertilizer Making Machine

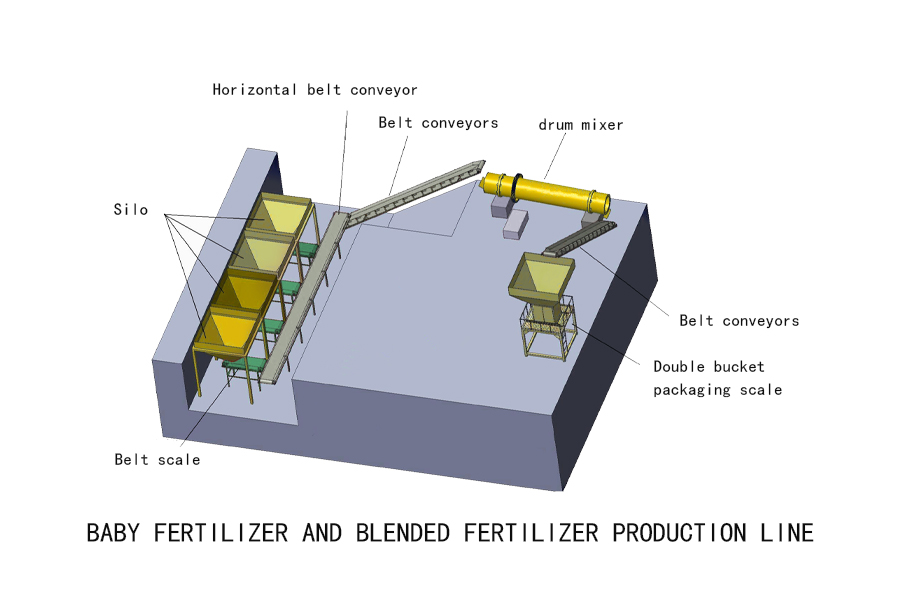

The BB Fertilizer Making Machine is designed for producing bulk blended fertilizers that cater to specific crop nutrient requirements. Its transportation characteristics are particularly noteworthy; this machine not only facilitates easy loading and unloading but also ensures minimal product degradation during transit. Furthermore, its compact design allows for efficient space utilization in transport vehicles, thereby reducing shipping costs. The integration of advanced scheduling and dispatching features enhances logistical efficiency by allowing real-time tracking and management of shipments.

Exploring Organic Fertilizer Granulation Machines in Scheduling and Dispatching

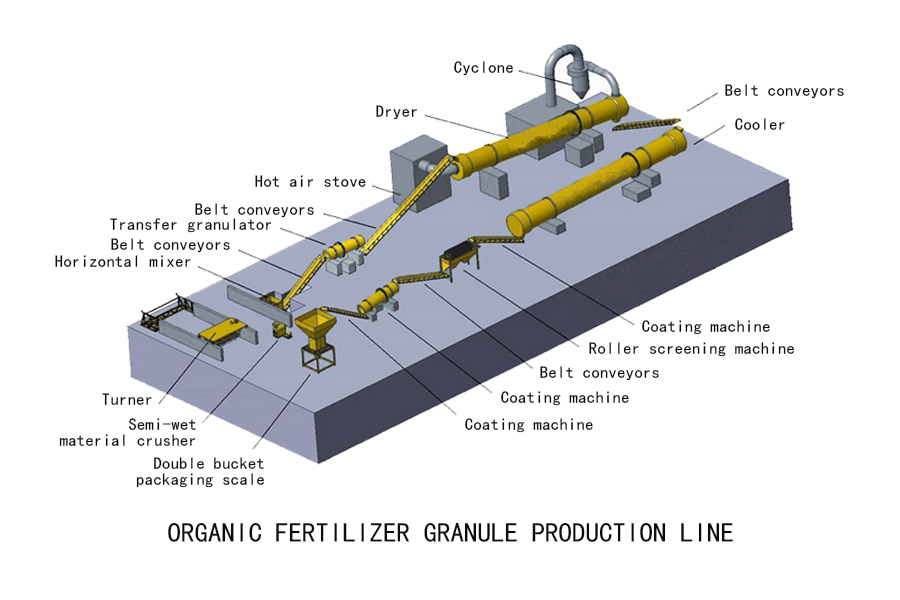

organic fertilizer granulation machines play a crucial role in enhancing scheduling and dispatching capabilities within fertilizer logistics. These machines produce uniform granules that are easier to handle during transportation compared to powdered forms. Their operational efficiency allows manufacturers to optimize production schedules based on demand forecasts, thus improving inventory management. Additionally, with automated dispatch systems integrated into organic fertilizer granulation processes, companies can ensure timely deliveries while minimizing delays caused by manual handling or miscommunication.

A Detailed Examination of Xincheng’s Scheduling and Dispatching Features

Xincheng has established itself as a leader in innovative scheduling and dispatching solutions tailored for fertilizer manufacturing operations. Their approach incorporates sophisticated software tools that analyze data from various sources—such as production rates, order volumes, and delivery timelines—to create optimized routing plans for transport vehicles. This capability significantly reduces lead times while ensuring that products arrive at their destinations fresh and intact. Moreover, Xincheng’s commitment to continuous improvement means they regularly update their technologies to adapt to changing market demands.

Conclusion

In summary, the BB Fertilizer Making Machine plays an essential role in enhancing transportation efficiency through its unique features related to scheduling and dispatching processes. By facilitating better load management, reducing product loss during transit, and integrating advanced logistical strategies like those offered by Xincheng’s innovations, this machinery contributes significantly towards meeting both producer needs and consumer expectations within the burgeoning global fertilizer industry.