When it comes to supplier/partner selection strategies, the utilization of advanced machinery plays a crucial role. One such machine that has revolutionized the manufacturing industry is the cnc drilling center. With its precision and efficiency, this equipment has become an indispensable tool for businesses seeking reliable suppliers or partners.

The Precision and Efficiency of CNC Drilling Center

The CNC drilling center offers unparalleled precision in hole drilling operations. Its computer-controlled system ensures accurate positioning and depth control, resulting in high-quality products with minimal errors. Moreover, this machine operates at a faster speed compared to traditional drilling methods, increasing productivity and reducing production time.

In addition to its precision and efficiency, the CNC drilling center also provides versatility in terms of hole sizes and shapes. It can accommodate various drill bits and cutting tools, allowing manufacturers to produce complex components with ease. This flexibility enables businesses to meet diverse customer demands while maintaining consistent quality standards.

Conprofe Ultrasonic: A Reliable Partner for CNC Drilling Centers

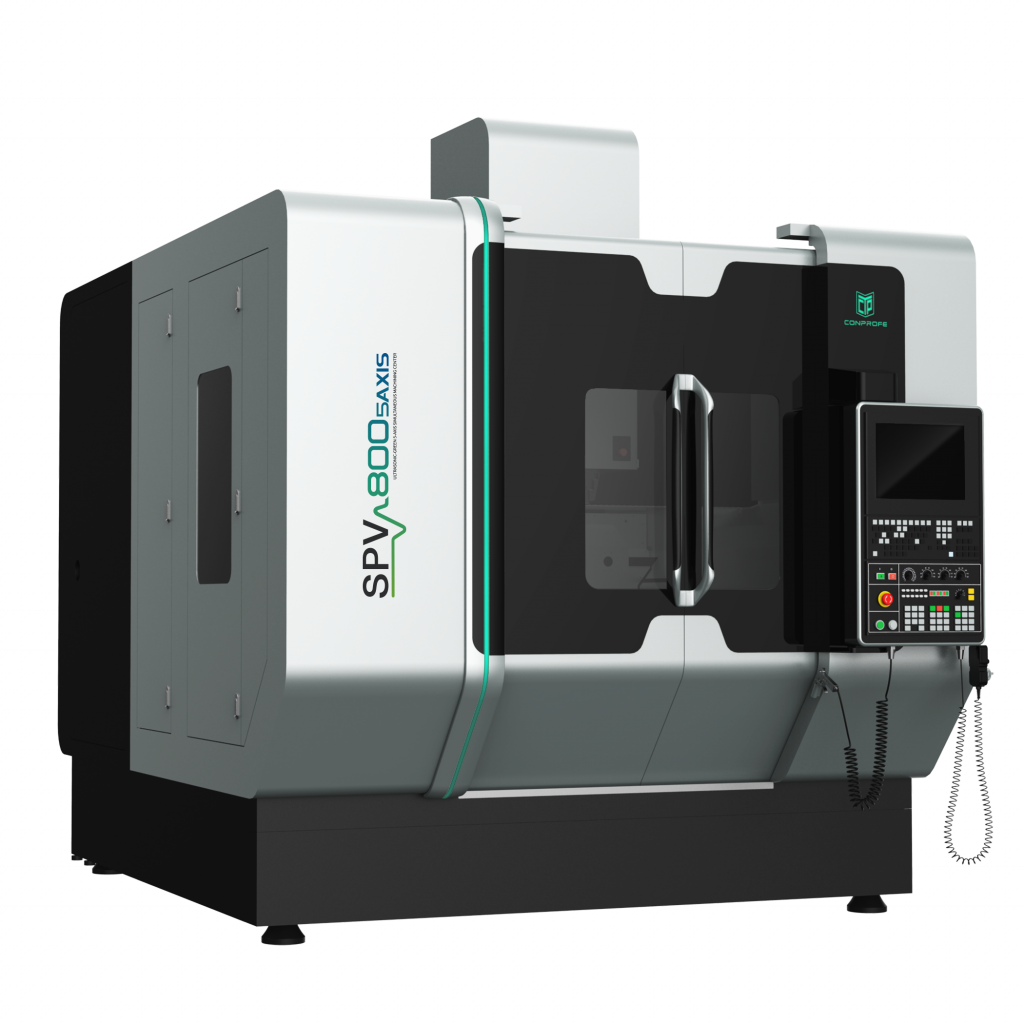

When selecting suppliers or partners for your CNC drilling center needs, Conprofe Ultrasonic stands out as a reputable choice. With years of experience in manufacturing ultrasonic machining equipment, they have established themselves as industry leaders in providing innovative solutions.

Conprofe Ultrasonic’s range of products includes state-of-the-art ultrasonic machining centers specifically designed for use with CNC drilling machines. These centers offer enhanced stability during operation, ensuring precise results even when working on challenging materials like ceramics or composites.

In addition to their exceptional product quality, Conprofe Ultrasonic also offers comprehensive technical support services. Their team of experts is readily available to assist customers with installation guidance, troubleshooting issues, or any other concerns related to their CNC drilling centers. This level of support ensures a seamless integration of the equipment into your manufacturing processes.

Graphite Machining Center for Sale: Expanding Capabilities

Another aspect to consider in supplier/partner selection strategies is the availability of additional machining capabilities. Graphite machining centers, such as those offered by Conprofe Ultrasonic, can greatly enhance your production capabilities and open up new opportunities for growth.

A graphite machining center allows for precise milling and shaping of graphite materials, which are widely used in industries like aerospace, automotive, and electronics. By investing in this technology through a reliable supplier like Conprofe Ultrasonic, you can expand your product offerings and cater to a broader market segment.

Furthermore, with their expertise in ultrasonic machining technology, Conprofe Ultrasonic provides comprehensive training programs for operating graphite machining centers effectively. This ensures that you maximize the potential of this equipment while maintaining optimal productivity and quality standards.

In Conclusion

The utilization of CNC drilling centers offers numerous advantages when it comes to supplier/partner selection strategies. Their precision, efficiency, versatility, combined with reliable suppliers like Conprofe Ultrasonic offering advanced solutions such as ultrasonic machining centers or graphite machining centers for sale significantly contribute to enhancing manufacturing capabilities. Incorporating these technologies into your operations will undoubtedly lead to improved productivity and customer satisfaction.

Click graphite machining center for sale.